5-axis CNC Milling, CNC Turning with Live Tooling, Direct Metal Additve Manufacturing (DMLS)

Scalmalloy® aluminum alloy

Hybrid powertrain components and structural elements for Formula Student race car

Manufacturing lightweight, high-stress parts with optimized geometries to maximize vehicle performance and reliability under race conditions; supporting a student-led motorsport team with fast, high-quality production cycles

CRP Meccanica is proud to partner with MoRe Modena Racing (MMR), the Formula Student team of the University of Modena and Reggio Emilia, through a two-year renewable technical agreement. The collaboration provides the students with access to high-precision CNC machining and production know-how—turning ambitious CAD models into fully functional race-ready components.

For CRP Meccanica, it’s not just about machining parts. It’s about accelerating innovation and investing in the next generation of engineers.

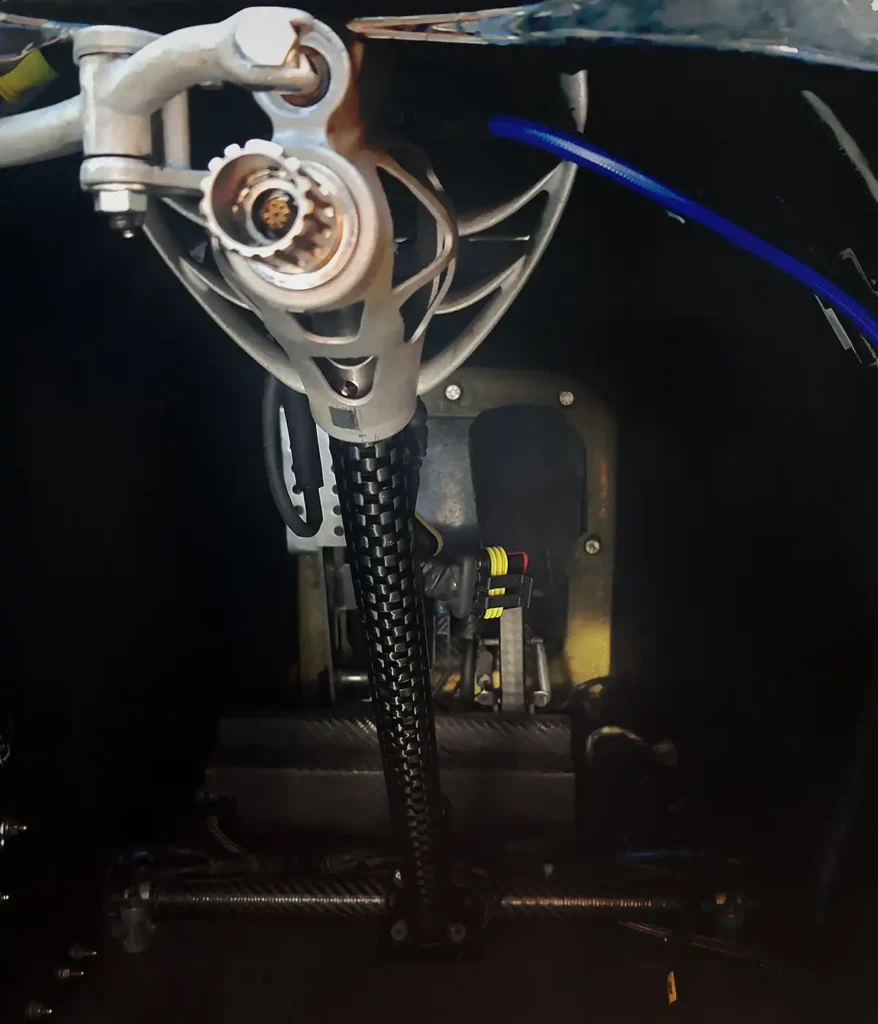

MMR’s 2024 prototype, the M24-LH, features two standout components manufactured with CRP Meccanica’s contribution: the steering support and the clutch lever.

Both were produced using Scalmalloy, an advanced aluminum alloy optimized through metal 3D printing. CRP Meccanica completed the production with state-of-the-art CNC machining, achieving the tight tolerances and mechanical integrity required for race conditions.

The steering support, designed with topological optimization and generative stress analysis, balances extreme lightness with structural rigidity. These designs are impossible to manufacture using traditional subtractive processes alone—which is where CRP’s hybrid expertise bridges the gap.

All were machined to exceptional precision, enhancing vehicle performance while reducing unnecessary weight. Each component is tailored to the hybrid drivetrain’s specific needs.

The M24-LH is the result of hands-on research and bold design choices:

This isn’t just a student car. It’s a testbed for real-world innovation, built with support from companies that push technology forward—like CRP Meccanica.

The MMR team highlighted the value of working with CRP:

“The support from CRP Meccanica was fundamental—not only for improving vehicle performance, but also for developing our engineering skills. The availability and professionalism of their team inspired us throughout the process.”

CRP Meccanica’s investment in this partnership reflects its long-term vision: developing cutting-edge solutions, while supporting young talent that will shape the future of automotive and motorsport innovation.

In 2025, CRP Meccanica renewed its technical support for MoRe Modena Racing, the Formula Student team from the University of Modena and Reggio Emilia. For the new hybrid car M25-LH, CRP Meccanica contributed a set of high-precision mechanical components, including CNC machined spindles from billet aluminum, produced using advanced 5-axis machining; CNC machined planetary gearboxes in billet Aluminum; Aluminum inserts for Carbon fiber control arms, CNC machined from solid; CNC finishing on 3D printed Titanium front brake calipers, fitted with DLC-coated billet pistons.

The synergy between CRP Meccanica’s manufacturing expertise and the students’ engineering talent led to a major achievement: 2nd place overall at Formula Student Austria 2025, held at the Red Bull Ring.

We support projects where performance matters – on the track or in the lab. Let’s build it together