5-axis CNC Milling, Direct Metal Laser Sintering (DMLS), Wire EDM, Precision Lapping

Aluminum Alloys (7075-T6, Scalmalloy®), Titanium Alloys

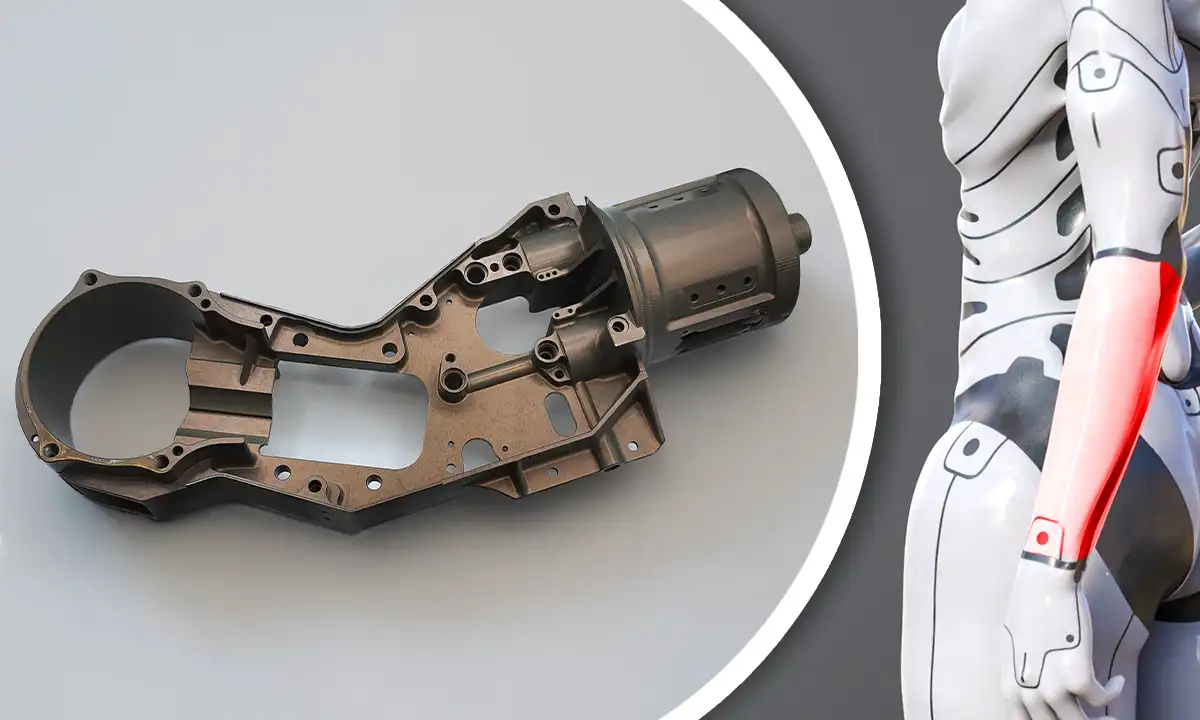

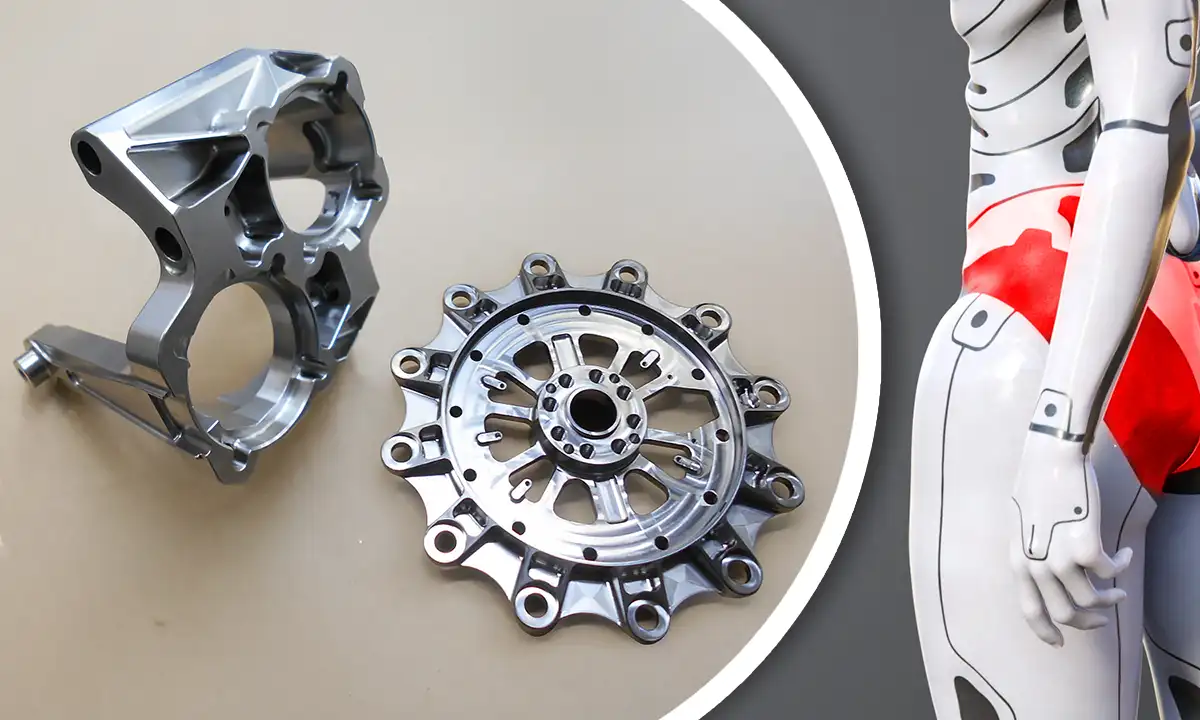

Mechanical and structural components for advanced humanoid robotics

Machining thin-walled aluminum and high-strength titanium components with extreme precision and tight tolerances, ensuring structural stability and precise assembly

As the robotics sector pushes toward human-like performance, the demand for ultra-precise, lightweight, and compact components has never been higher. In collaboration with global leaders in humanoid robotics, CRP Meccanica was selected to manufacture complex structural and mechanical parts for a new generation of humanoid platforms.

The customer needed a partner capable of producing mission-critical components with micron-level accuracy, while also supporting engineering decisions and ensuring seamless integration across mixed technologies.

The result: a comprehensive production approach combining DMLS, CNC milling, EDM, and lapping for uncompromised results.

These parts featured wall thicknesses down to 1.5 mm, which caused vibration and potential warping during post-processing. Standard clamping methods proved insufficient.

Solution: A custom support jig was 3D printed in Windform composite to reinforce the structure during CNC machining.

Dimensional precision within ±0.01 mm was achieved without distortion, even on ultra-thin walls.

Hydraulic cylinders required tolerances of ±5 µm across deep bores in 7075-T6 aluminum, demanding both rigidity and surface consistency.

Solution: A combined process of precision boring, multi-axis adaptive machining, and final lapping minimized tool pressure and material deformation.

±0.005 mm consistency across pockets and a surface finish suitable for smooth, long-life hydraulic performance.

Structural components in titanium alloy were prone to tool wear and work hardening. The hip torque cell required a surface finish of Ra ≤ 0.2 µm for accurate force measurements on strain gauges.

Solution: High-speed machining with custom carbide tools and precision lapping for final finishing.

Aerospace-grade quality, increased tool life, and structural durability for dynamic load environments.

The foot structure combined lightweight design with rigid precision zones—manufactured using Scalmalloy® via DMLS, followed by 5-axis CNC refinement.

Additionally, the titanium connector plate was machined using wire EDM and CNC milling, reaching tolerances of ±5 µm.

A fully integrated hybrid assembly, maintaining total assembly precision of ±0.01 mm and ensuring drop-in compatibility with the robot’s structural architecture.

All manufactured under EN 9100-certified quality and delivered with full engineering support.

Tolerances | Surface finish | Wall thicknesses | Hybrid component assembly tolerance |

|---|---|---|---|

as tight as ±5 µm | Ra ≤ 0.2 µm | down to 1.5 mm | ±0.01 mm |

The client sought more than machining—they needed a consulting partner, capable of:

CRP Meccanica met every requirement with agility and precision, reinforcing its reputation in advanced robotics manufacturing.

Let’s bring precision, lightness, and strength together—micron by micron.