5-axis CNC milling, high-precision CNC turning, hard anodizing, final honing, manual deburring

Aluminium 2014 alloy

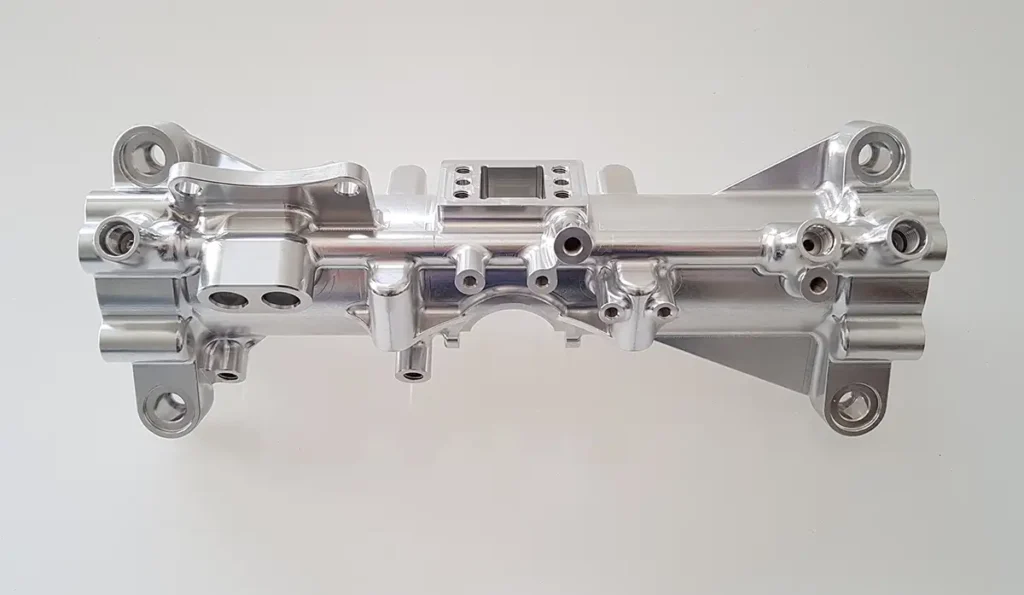

A high-performance power steering rack housing for racing cars, integrating steering, hydraulic channels, and actuator interfaces

Manufacture a complex, safety-critical component with intersecting bores and tight tolerances. Ensure structural integrity, wear resistance, and leak prevention under extreme racing conditions.

CRP Meccanica has been a trusted partner in the motorsport sector for over 50 years. Among its standout achievements is the development and machining of power steering rack housings—core components in advanced racing car steering systems.

From the early days of manual rack-and-pinion systems to today’s integrated hydraulic-assisted architectures, CRP Meccanica has evolved its process, materials, and machining expertise to meet increasingly demanding performance standards.

The power steering rack housing is a multi-functional component. It houses the rack, guides pressurized oil through a series of intersecting internal bores, and supports hydraulic actuators. These internal geometries require not only extreme precision, but also material-specific surface treatments to guarantee safe and reliable operation.

Each part is machined from high-strength aluminum alloys—initially Aluminum 2014, now superseded in many cases by Aluminum-Lithium alloys for enhanced stiffness and reduced weight.

to maintain concentricity across axes

for bore alignment and internal features

for external forms and tight transitions

To prevent premature wear of the hydraulic actuator inside the rack housing, CRP Meccanica performs hard anodizing to a depth of 50–60 microns. This creates a hard, wear-resistant, non-reactive coating on the inner surfaces that maintain actuator seal integrity and prevent aluminum degradation.

This is followed by precision honing of the internal bores to guarantee the correct diameter and smoothness for the piston seal to function perfectly under pressure.

The internal structure of the rack housing includes multiple intersecting channels, controlled by solenoid valves for oil flow regulation. These intersections naturally create burrs during machining—tiny fragments that can become dangerous debris under pressurized oil flow.

CRP Meccanica uses manual deburring techniques combined with targeted toolpaths to completely remove sharp edges. Every bore is inspected to eliminate loose particles that could lead to seizure or system failure.

“Burrs are never just aesthetic issues,” states CRP’s Engineering Director. “In hydraulic systems, they can cause serious damage. That’s why our team dedicates the same attention to burr removal as to machining tolerances.”

CRP Meccanica’s method combines experience, material science, and modern CNC technology. From F1 to the latest electric powertrains, the company has continuously refined its ability to machine the most complex geometries without sacrificing speed or repeatability.

In this application, nothing is left to chance—from the anodizing layer to the final test. Every part is made in small runs or prototypes, tailored to the customer’s spec, and validated for high-pressure, high-speed environments.

Do you need a high-performance component engineered with zero margin for error?

We’ve been doing just that since 1970.