Additive Manufacturing (3D printing) of casting patterns, titanium Rapid Casting, Precision CNC Machining

Titanium alloy

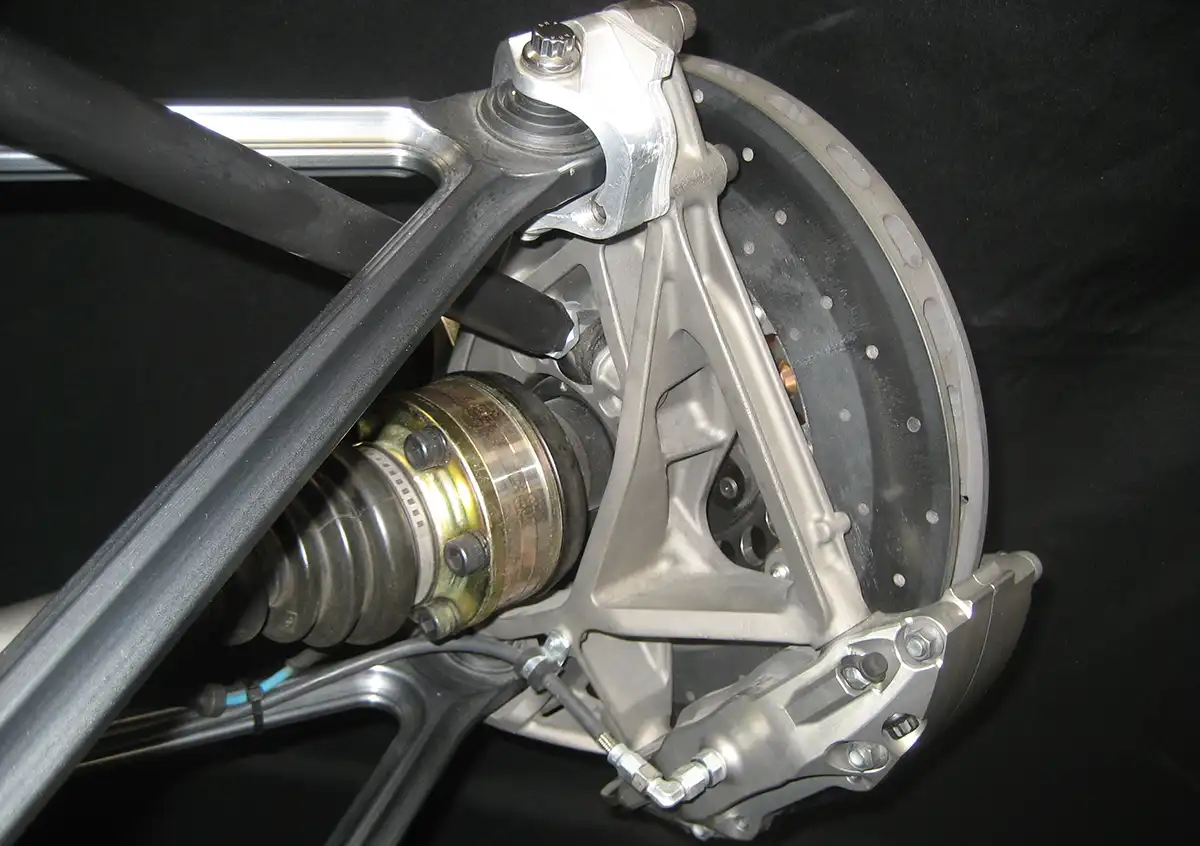

High-performance structural uprights for Kepler Motors’ MOTION hypercar suspension system

Achieving lightweight yet robust titanium suspension uprights with complex geometries and stringent load-bearing requirements, unattainable through traditional manufacturing methods

When Kepler Motors set out to build the MOTION, a hypercar capable of accelerating from 0 to 60 mph in under 2.5 seconds, they knew traditional manufacturing wouldn’t be enough. For critical parts like the suspension uprights, which connect the wheels to the car’s double wishbone pushrod suspension, they demanded maximum strength and minimum weight – with no design compromises.

That’s where CRP firms came in.

Kepler’s engineering team reimagined the upright from scratch, designing it for performance first, not around manufacturing constraints. By working with CRP USA and CRP Meccanica, they gained access to a hybrid production chain: additive manufacturing, investment casting, and CNC machining.

Using Selective Laser Sintering, CRP created the complex upright geometry as a 3D printed pattern—free from the limitations of traditional mold design. This allowed for internal features, smooth load paths, and tight integration with surrounding systems.

The printed pattern was used to cast the upright in titanium, a material chosen for its superior strength-to-weight ratio, rigidity, and heat resistance. Unlike aluminum – often used in uprights but bulky and less durable – titanium enables thinner walls and greater design flexibility without compromising mechanical integrity.

CRP Meccanica then performed high-precision CNC machining to meet the demanding tolerances required for proper alignment of bearings, linkages, and fasteners. Every face, hole, and angle had to be machined to perfection.

Multiple load cases were validated through Finite Element Analysis (FEA), ensuring the part would handle extreme braking, cornering, downforce, and acceleration—all of which act simultaneously on a hypercar upright.

The result: an elegant, lightweight structure that is functional, robust, and ready for racing-grade street performance.

All under one coordinated process.

Kepler Motors selected CRP firms because of its Formula 1 DNA and ability to manage complexity. The result was a part no other supplier could have achieved:

lighter, stronger, more accurate, and delivered on time.

CRP Meccanica made design freedom real – without compromise, delay, or error.

Let’s take your next innovation off the whiteboard and onto the road – or the track.